Dryrod Damp-Proofing Rods

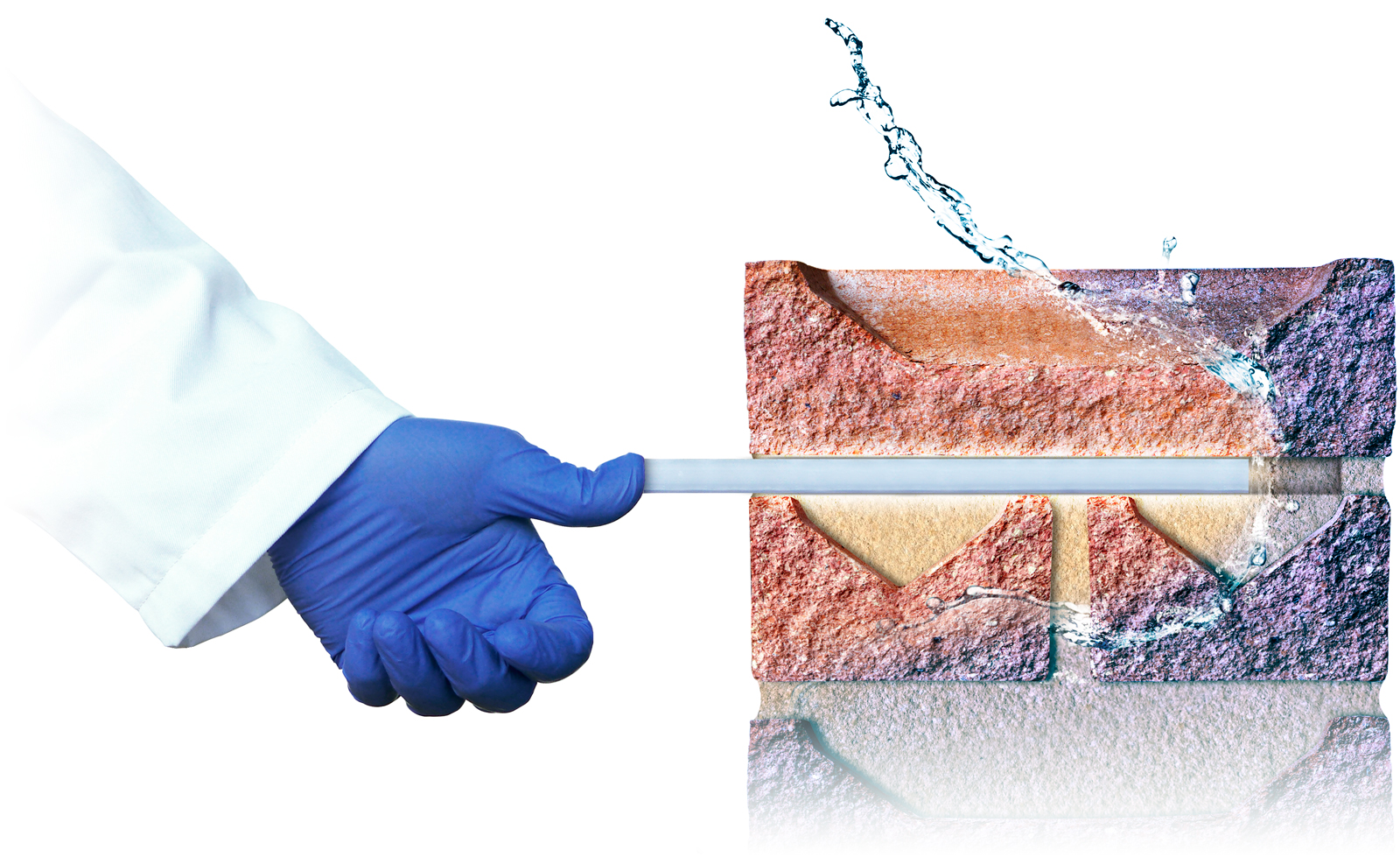

Dryrod Damp-Proofing Rods are the next generation treatment for rising damp. They provide a higher level of performance and quicker installation speed than any other rising damp treatment currently available.

Dryrods are 12 mm diameter, 180 mm length, fibre rods that contain a powerful water repellent. The patented, and BBA-approved, Dryrod delivery system ensures the correct dose of active ingredient is delivered to the wall every time, permanently eradicating rising damp.

No fuss, no mess, no stress.

Why use Dryrod?

As the latest development in the treatment of rising damp, there are numerous advantages to using Dryrod Damp-Proofing Rods:

- The most effective form of rising damp treatment available — Dryrod outperforms all tested competitor products.

- Extremely quick and simple to install — Simply drill holes in a continuous mortar course and insert the required number of damp-proofing rods.

- Permanent eradication of rising damp — The active ingredient contained within the rods spreads through, and bonds with, the mortar in a wall, providing a permanent solution to rising damp.

- No specialist equipment required — No costly pumps or lances are needed and only standard tools are required.

- No chemical mess to clean up — Conveniently foil-wrapped packaging and a simple installation procedure means no spillages.

- Delivers the correct dose every time — Each rod is accurately dosed with exactly the correct amount of water-repellent.

- Proven to work on highly-saturated walls (even up to 95% saturation) — Tests show that Dryrod Damp-Proofing Rods outperform even premium damp-proofing creams at high saturation levels.

- Low-hazard — Dryrod Damp-Proofing Rods are solvent free, odour free and non-caustic.

The Importance of Effective Damp-Proofing

Naturally, homeowners want the most effective products available to be used to treat rising damp in their properties. Creating the best possible barrier to rising damp minimises moisture in the wall, blocks the build-up of ground salts, and reduces heat-loss. For this reason, Dryrod Damp-Proofing Rods have been designed to form an effective DPC in walls of all types and have been tested under conditions of up to 95% saturation, where it has been shown to outperform all tested competitor products.

This is important because no two walls suffering from rising damp are the same. In particular the physical properties of the mortar used to construct walls can vary considerably and this can have a significant influence on the effectiveness of any rising damp treatment.

Dryrod Damp-Proofing Rods are effective in a wide range of conditions, including:

- Saturated walls (up to 95% saturation)

- Low alkalinity mortar

- High alkalinity mortar

- Low porosity mortar

- High porosity mortar

- Lime-based mortar

- Cement-based mortar

Treating Walls of Varying Thicknesses With Dryrods

Although Dryrods are designed to treat standard 9 inch double skin brick walls, the rods can be cut to the appropriate size using the Dryrod cutting tool. For walls thicker than 9 inches, it is possible to combine up to 2 rods per hole, cutting the second rod to fill any excess space left over by the first. The following table can be used as a cutting guide for various wall thicknesses:

Wall Thickness

| 4½″ (115 mm) | 9″ (230 mm) | 13½″ (345 mm) | 18″ (460 mm) | |

|---|---|---|---|---|

| Depth of Drill Hole | 95 mm | 210 mm | 325 mm | 440 mm |

| Length of Dryrod | 90 mm | 180 mm | 270 mm | 360 mm |

Dryrod Application

-

Mark your drill bit to the appropriate depth for the wall you wish to treat. A Dryzone 12 mm Drill Bit is recommended for enhanced debris removal.

-

Set your SDS drill to rotary hammer mode and attach the suitably marked drill bit.

-

Identify the lowest horizontal mortar course that is accessible and continuous. Drill holes to the full recommended depth, at regular 120 mm intervals along the wall. As the drill bit approaches the final 40 mm of the intended hole depth, make sure to reduce the pressure you are putting on the drill. Excessive drilling pressure on the rotary hammer setting can result in damage to the far side of the wall.

-

If debris obstructs the insertion of the damp-proofing rods, the Dryzone System Hole-Clearing Tool can be used to ensure the hole is completely clear.

-

A standard Dryrod Damp-Proofing Rod is 180 mm in length, which is the exact length required to treat a standard 9″ wall. If the wall is thinner than 9″ then cut the rods down until they are 10 mm shorter than the length of the hole. If the wall is thicker than 9″, cut a second rod down until its length is 10 mm less than the excess left after inserting one whole rod.

-

Fully insert the rods into each hole, ensuring that the rods are recessed approximately 5 mm from the brick face, taking care not to compress the rods against the back of the holes.

When installing internally, the performance of the rod will not be affected if the rods protrude slightly from the mortar, as a result of it being eroded at the surface. As long as the rod is inserted to the correct depth at the far side of the wall, full treatment will be accomplished and any protruding rods will be covered during redecoration.

Once the damp-proofing rods are installed, they diffuse the active ingredient deep into the wall before it cures to form a water-repellent barrier. This prevents the damp from rising up the wall.

Coverage

Number of rods required per 10 m stretch of wall:

| Wall Thickness | ||||

|---|---|---|---|---|

| Wall Length | 4½″ (115 mm) | 9″ (230 mm) | 13½″ (345 mm) | 18″ (460 mm) |

| 10 m | 42 rods | 84 rods | 125 rods | 167 rods |

More information is contained in our guide to Rising Damp & its Control.

Replastering

As with all remedial damp-proofing systems, it is necessary to remove and replace any salt-contaminated plaster. The introduction of our hybrid plasterboard method, the Dryzone Express Replastering System has greatly simplified this process. See our page on replastering as part of a rising damp treatment for details of replastering systems available.

For heritage projects, or where replastering needs to be minimised Dryzone Renovation Plasters should be used.

| Appearance | White, cog-shaped solid fibre rod | |

|---|---|---|

| Size(s) & Packaging | Pack of 10 rods of 180 mm length and 12 mm diameter | |

| Coverage (per 10 m of wall) [1] | ||

| 4½″ thick wall | 42 rods | |

| 9″ thick wall | 84 rods | |

| 13½″ thick wall | 125 rods | |

| 18″ thick wall | 167 rods | |

| Service Life | At least 20 years | |

| Storage | Store flat and in a cool, dry place | |

| Shelf Life | 12 months in unopened pack | |